In recent years, the manufacturing industry has been witnessing a steady rise in innovation and technological advancements. Among the many ground breaking developments, the In-Mold Coatings Market has emerged as a significant player, revolutionizing the way products are finished and enhancing their aesthetic appeal. In this blog post, we delve into the dynamics of the in-mold coatings market, its benefits, applications, and prospects.

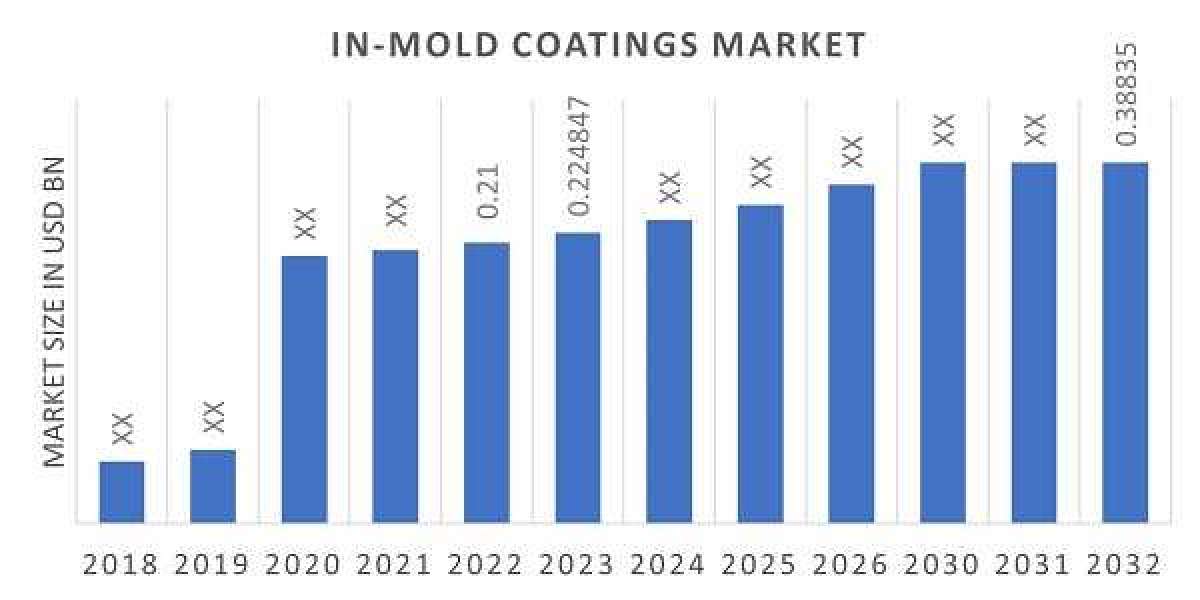

The In-Mold Coatings Market sector is projected to witness the highest CAGR of 7.07% growing from USD 0.21 billion in 2022 to USD 0.388355552 billion by 2032

Understanding In-Mold Coatings:

In-mold coatings, also known as IMC, refer to a specialized coating process wherein a coating material is applied to a mold before the manufacturing process begins. This innovative technique is primarily employed in industries such as automotive, electronics, appliances, and packaging. The coating material fuses with the molded substrate during the manufacturing process, resulting in a seamless, durable, and visually appealing finish.

Key Advantages:

The increasing popularity of in-mold coatings can be attributed to a range of benefits they offer:

Enhanced Aesthetics: IMC enables manufacturers to achieve high-quality finishes with intricate designs, textures, and patterns. This is especially crucial in industries where visual appeal plays a vital role in consumer preference.

Durability: The in-mold coatings bond chemically with the substrate, enhancing the durability and longevity of the finished product. This resistance to wear, abrasion, and environmental factors is a significant advantage, particularly in applications exposed to harsh conditions.

Efficiency: The in-mold coating process eliminates the need for secondary finishing steps, reducing production time and costs. This efficiency gain contributes to streamlined manufacturing processes.

Environmental Friendliness: IMC often utilizes low-VOC (volatile organic compound) coatings, contributing to a more sustainable production process and reducing the environmental impact.

Diverse Applications:

The versatility of in-mold coatings is reflected in their broad range of applications:

Automotive Industry: In-mold coatings are extensively used in the automotive sector for components like interior panels, trims, and dashboards. The ability to achieve high-gloss or matte finishes with consistent quality has made IMC a preferred choice in this industry.

Electronics: In the electronics sector, IMC is employed in the production of items like mobile phone casings, laptop covers, and other consumer electronic products. The coatings provide not only an attractive appearance but also protection against scratches and wear.

Packaging: In-mold coatings are finding applications in the packaging industry, enhancing the visual appeal of packaging materials for consumer goods.

Appliances: The appliance industry benefits from the durability and aesthetics that in-mold coatings offer, making products like refrigerators, washing machines, and ovens more attractive and resistant to daily wear.

Outlook:

As technology and materials continue to evolve, the in-mold coatings market is poised for further growth. Advancements in coating formulations, improved bonding techniques, and expanding application areas are expected to drive the adoption of IMC across industries. Additionally, the increasing focus on sustainable manufacturing processes will likely lead to the development of even more eco-friendly coating options, further enhancing the market's attractiveness.

In conclusion, the in-mold coatings market presents a compelling solution to manufacturers seeking enhanced aesthetics, durability, and efficiency. With its diverse applications and undeniable advantages, IMC is shaping the future of product finishing. As industries continue to embrace this innovative technology, we can expect to see an exciting evolution in manufacturing processes and product aesthetics.

About Market Research Future:

Market Research Future (MRFR) is a global market research company that takes pride in its services, offering a complete and accurate analysis about diverse markets and consumers worldwide. Market Research Future has the distinguished objective of providing the optimal quality research and granular research to clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help answer your most important questions.

Contact:

Market Research Future (Part of Wantstats Research and Media Private Limited)

99 Hudson Street, 5Th Floor

New York, NY 10013

United States of America

+1 628 258 0071 (US)

+44 2035 002 764 (UK)

Email: sales@marketresearchfuture.com

Website: https://www.marketresearchfuture.com