Market Overview:

According to MRFR analysis, Globally, The Factory Automation market industry is projected to grow from USD 187.48 Million in 2022 to USD 325.01 Million by 2030, exhibiting a compound annual growth rate (CAGR) of 7.12% during the forecast period (2022 - 2030).

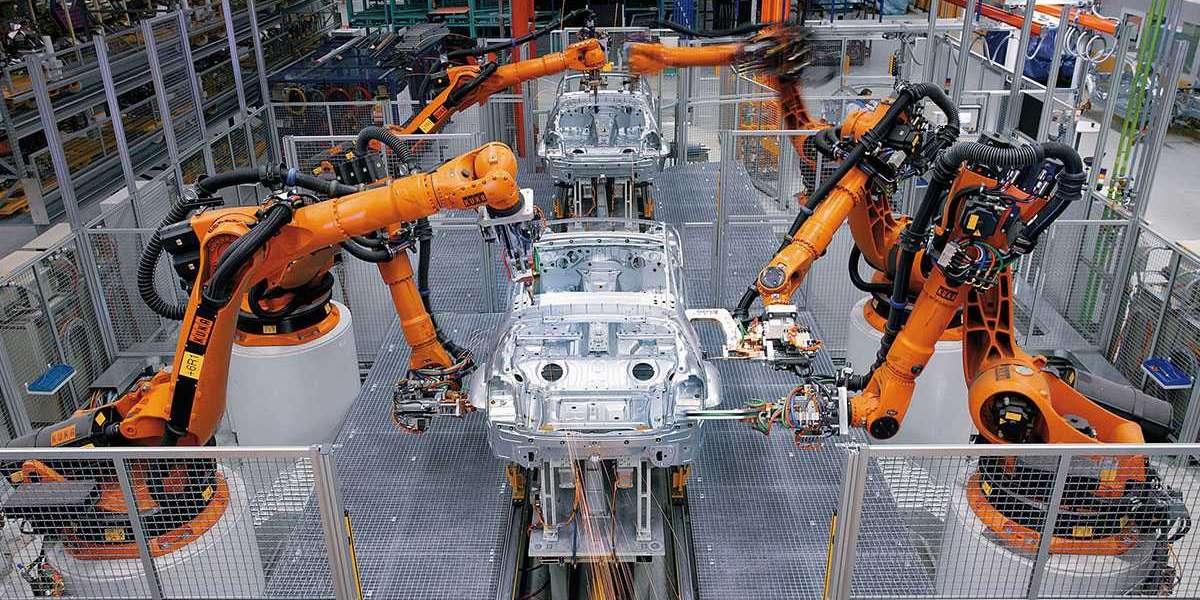

The factory automation market is rapidly expanding due to the widespread acceptance of automation technology in various industries, including oil and gas, automotive, manufacturing petrochemicals and materials, chemicals, and pharmaceuticals. More recently, labor costs can be reduced by implementing automation technologies such as sensing devices, robotics, machine vision systems, and enterprise control solutions. In addition, automation and robotics are increasingly being used by manufacturing and service providers to meet the increasingly complex expansion of the industrial automation market.

Real-time data analysis and increasing maintenance of developed technologies to improve the visibility of the factory are the major factors driving growth of the global factory automation market. Asset management solutions with improved connectivity and simple workflow and data transfer. Increased research and development, along with the development of technology and improved solutions and predictive maintenance of machinery, have reduced labor costs, reduced heavy lifting in the manufacturing process, and improved automation by reducing process steps.

"Request Free Sample" - https://www.marketresearchfuture.com/sample_request/3565

Regional Analysis

North America dominates the global factory automation market. Factors such as the presence of key industry players and advances in technologies drive the market growth. Besides, the rising demand for the automation of industrial processes boosts the market size. The US holds the leading share in the regional market, followed by Canada.

Moreover, stringent government regulations to implement industrial safety technologies and the steady rise across end-user industries create substantial market demand. Also, the augmenting demand for safety and comfort features positively impacts regional market growth. Furthermore, the growing uptake of factory automation in manufacturing sectors across the region fosters market revenues.

Competitive Analysis

Highly competitive, the factory automation market appears fragmented due to the presence of several well-established players. Industry players incorporate strategic approaches such as mergers acquisitions, collaborations, expansion, and product/ technology launch to gain a larger competitive share.

Key Players:

The key players of the Factory Automation market include ABB, Emerson Electric Co., Mitsubishi Electric Corporation, General Electric, Rockwell Automation, Inc., Omron Corporation, Honeywell International Inc., Schneider Electric SE, Siemens AG, Yokogawa Electric, Fanuc Corporation, Hitachi, Roberth Bosch GMBH, Danfoss and Danaher Corporation.

Introduction:

In today's fast-paced industrial landscape, businesses are constantly seeking ways to enhance efficiency, reduce costs, and improve productivity. One remarkable solution that has been revolutionizing the manufacturing sector is factory automation. By harnessing the power of advanced technologies, factory automation is transforming traditional production processes into intelligent, streamlined operations. In this blog post, we will delve into the fascinating world of factory automation, exploring its benefits, current trends, and future prospects.

The Rise of Factory Automation:

Factory automation refers to the implementation of innovative technologies, such as robotics, artificial intelligence (AI), Internet of Things (IoT), and data analytics, to optimize manufacturing processes and minimize human intervention. The market for factory automation has been witnessing rapid growth in recent years, and its potential is far from being fully realized.

Benefits of Factory Automation:

- Enhanced Efficiency: One of the primary advantages of factory automation is the significant improvement in operational efficiency. By automating repetitive tasks and utilizing intelligent systems, businesses can eliminate human errors, reduce cycle times, and achieve consistent quality levels. This allows for faster production rates and a higher output of goods.

- Cost Reduction: Factory automation can contribute to cost savings through various means. Automated systems require fewer labor resources, minimizing workforce expenses. Additionally, automation leads to better resource utilization, reduced material wastage, and optimized energy consumption, resulting in substantial cost savings in the long run.

- Improved Safety: Dangerous and hazardous tasks in manufacturing can be delegated to robots, ensuring the safety of workers. Automation reduces the risk of accidents, injuries, and exposure to harmful environments, thus enhancing workplace safety.

Current Trends in Factory Automation:

- Collaborative Robots (Cobots): The integration of cobots in manufacturing processes is gaining momentum. These robots work alongside humans, assisting with tasks that require precision, heavy lifting, or repetitive motions. Cobots can be easily programmed, are flexible, and promote efficient human-robot collaboration.

- Industrial IoT (IIoT): The adoption of IIoT enables seamless connectivity and data exchange between machines, sensors, and systems within a factory. This connectivity allows for real-time monitoring, predictive maintenance, and remote control of machinery, leading to proactive decision-making and improved productivity.

- Artificial Intelligence and Machine Learning: AI and machine learning algorithms are transforming factory automation by enabling intelligent systems to learn, adapt, and optimize processes. These technologies enable predictive analytics, quality control, and autonomous decision-making, resulting in more efficient and self-optimizing manufacturing operations.

Future Prospects of Factory Automation:

- Integration of 5G: The deployment of 5G networks will enable faster and more reliable communication between machines and systems. This will facilitate real-time data transfer, remote control, and the implementation of advanced technologies, opening up new possibilities for factory automation.

- Edge Computing: Edge computing brings computational power closer to the production floor, reducing latency and enabling faster data processing. This will be crucial for handling the vast amount of data generated by IoT devices and ensuring real-time analysis and decision-making.

- Advanced Robotics: The development of advanced robotic systems, such as humanoid robots and mobile robots, will further enhance factory automation. These robots will possess greater dexterity, agility, and adaptability, expanding their application areas beyond traditional manufacturing tasks.

Related Reports

Industrial Robotics Market - http://icrowdnewswire.com/industrial-robotics-market-is-expected-to-grow-usd-40-379-4-million-by-2030-industry-share-report

Automated Fingerprint Identification System Market - http://icrowdnewswire.com/automated-fingerprint-identification-system-market-is-estimated-to-register-a-cagr-of-over-26-9-by-2030

Conclusion:

Factory automation is reshaping the manufacturing industry, driving efficiency, productivity, and competitiveness. By embracing the latest technologies, businesses can unlock a multitude of benefits, including improved operational efficiency, cost reduction, and enhanced worker safety. As current trends continue to evolve and future prospects unfold, the potential for factory automation to revolutionize industrial processes is boundless. Embracing this transformative trend will be crucial for businesses to stay ahead in the dynamic and competitive landscape of manufacturing.