Market Insights:

According to the MRFR, The worldwide semiconductor inspection system market will reach USD 8.3 billion at a CAGR of 5.1% during the assessment period (2022-2030). The most recent technology advancements have made a significant contribution, in a significant way, to a dramatic shift in the inspection system for semiconductors. It is anticipated that the rising prevalence of the Internet of Things (IoT) and the introduction of linked gadgets would propel the general expansion of the global market for semiconductor inspection systems. The key forces behind the expansion of the industry are things like rising consumer demand for high-performance semiconductors at affordable prices. The development of the semiconductor inspection systems market is being driven by the elimination of production delays, which is one of the important benefits offered by semiconductor inspection systems. Other important benefits include the detection of equipment problems, durability, and high performance.

Industry News:

In September 2020, CyberOptics® Corporation, an eminent company making its name as a developer and manufacturer of high-precision 3D sensing technology solutions, are expected to launch, at the SEMICON Taiwan Global SiP Summit, their Fast, 100% 3D Wafer Bump Metrology and Inspection that would significantly transform yields and 3D system integration.

Advanced Packaging (AP) and wafer level packaging (WLP) are creating buzz in the evolving areas of semiconductor development and manufacturing. Such technologies are expected to benefit from CyberOptics’ contributions.

In August 2020, Israel's Camtek, a company known for its ability to manufacture metrology and inspection equipment and catering the needs of diverse segments of the semiconductor industry, announced that the company has received orders for multiple systems from a tier-one radio frequency (RF) device manufacturer that can be valued at $7 million.

The customer has gone for Camtek's advanced EagleT inspection system model. The remaining months of 2020 will witness the shipment and fixing of these tools. Camtek is anticipating additional orders that would be for the year 2021.

The global market report suggests that the market may remain unaffected due to the rising demand for cutting-edge products to support healthcare and consumer electronics segment. The initial setback due to the COVID-19 crisis is not going to persist for long as economies are taking measures to maintain normalcy.

"Request Free Sample" - https://www.marketresearchfuture.com/sample_request/1797

Key Players

Rudolph Technologies, Inc., JEOL Ltd., Hitachi High-Technologies Corp., Nanometrics, Inc., KLA-Tencor Corporation, Applied Materials, Inc., Nikon Metrology NV, Lasertec Corporation, Thermo Fisher Scientific, Inc., and ASML Holding NV are the key players in the global semiconductor inspection system market.

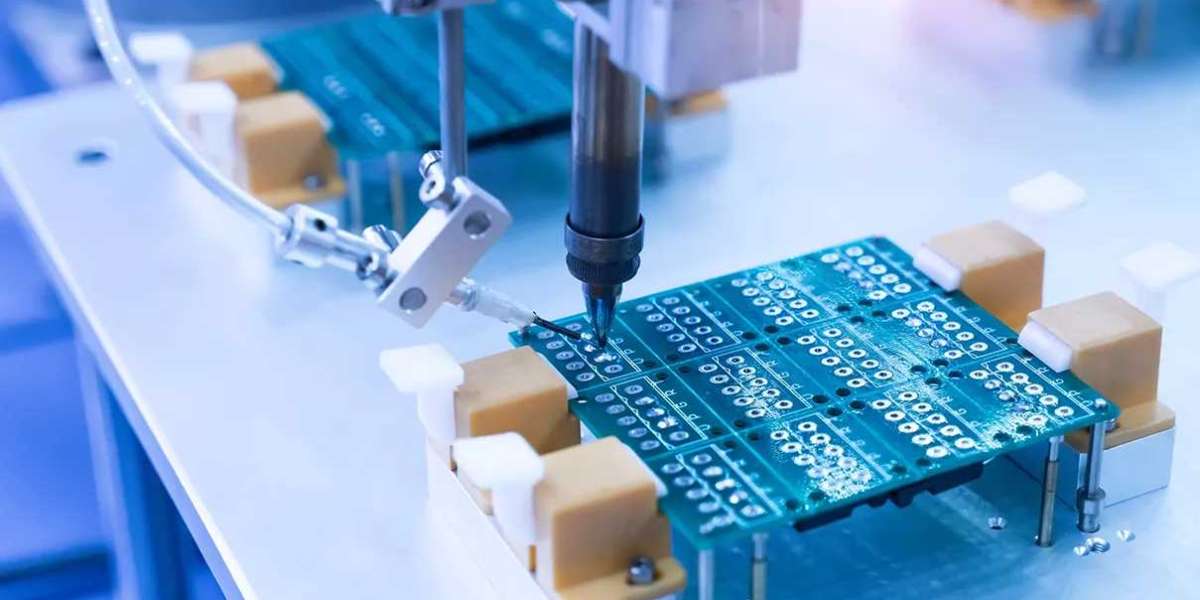

Understanding Semiconductor Inspection Systems

Semiconductor inspection systems are advanced tools designed to detect defects, faults, and irregularities in semiconductor wafers, chips, and other components during the manufacturing process. These systems utilize a combination of imaging, metrology, and machine learning techniques to ensure the production of high-quality and reliable semiconductor devices.

Key Market Drivers

The semiconductor inspection system market is witnessing substantial growth due to several key factors:

- Technological Advancements: Rapid advancements in imaging and metrology technologies, such as optical microscopy, electron microscopy, and X-ray imaging, have significantly enhanced the capabilities of semiconductor inspection systems. These advancements allow for the detection of even the tiniest defects, ensuring higher quality control.

- Increasing Complexity of Semiconductor Devices: As semiconductor devices become smaller and more complex, traditional inspection methods are unable to identify subtle defects. Semiconductor inspection systems offer superior accuracy and reliability in identifying defects at a microscopic level, meeting the stringent quality standards demanded by the industry.

- Growing Demand for Consumer Electronics: The global demand for consumer electronics, including smartphones, tablets, and wearable devices, continues to rise. This surge in demand necessitates the production of large quantities of semiconductors with minimal defects. Semiconductor inspection systems enable manufacturers to meet this demand by ensuring high-quality production at a faster rate.

- Stringent Safety Regulations: Industries such as automotive, aerospace, and healthcare have strict safety regulations and quality standards. Semiconductor inspection systems help manufacturers comply with these regulations by identifying potential defects and faults that could compromise the reliability and safety of the end products.

Market Segmentation

The semiconductor inspection system market can be segmented based on the type of inspection system and end-user industry.

Based on the type of inspection system, the market can be categorized into:

- Wafer Inspection Systems: These systems are primarily used for inspecting the quality and integrity of semiconductor wafers before they undergo further processing.

- Mask Inspection Systems: Mask inspection systems are utilized to examine the accuracy and quality of photomasks, which are essential in the fabrication process of semiconductor devices.

- Package Inspection Systems: Package inspection systems are designed to inspect the final packaged semiconductor devices for any defects or faults.

Based on the end-user industry, the market can be classified into:

- Electronics: The electronics industry is the largest consumer of semiconductor devices, making it a significant end-user of semiconductor inspection systems.

- Automotive: As automotive manufacturers increasingly integrate semiconductor components into vehicles, the need for high-quality inspection systems becomes imperative to ensure safety and reliability.

- Healthcare: The healthcare industry relies on semiconductor devices for various applications, such as medical imaging and diagnostic equipment. The use of inspection systems guarantees the accuracy and reliability of these critical devices.

- Aerospace and Defense: The aerospace and defense sectors demand highly reliable and durable semiconductor devices. Inspection systems play a crucial role in ensuring the quality of components used in these industries.

Related Reports:

Educational Robots Market - https://www.globenewswire.com/en/news-release/2023/04/29/2657925/0/en/Educational-Robots-Market-is-Predicted-to-Reach-USD-8-6-Billion-at-a-CAGR-of-18-00-by-2030-Report-by-Market-Research-Future-MRFR.html

Conclusion:

The semiconductor inspection system market is experiencing remarkable growth due to the increasing demand for high-quality semiconductor devices across various industries. The advancement of imaging and metrology technologies, coupled with the need for stringent quality control, has propelled the adoption of semiconductor inspection systems. As technology continues to advance and semiconductor devices become even more sophisticated, the importance of these systems in maintaining quality and reliability will only continue to rise.