Your search for the best palm oil processing plant in India ends here. Palm oil is the most traded vegetable oil in the world, and it is to reach 75.69 from 62.3 billion US dollars from 2021 to 2028 in India. Hence, the need for refining of palm oil has also increased in recent years. It is because extruded crude palm oil has many impurities like FFA or free fatty acid, carotenoids or coloring pigments, phospholipids, oxidative material, moisture, sugars, phenols, metal impurities, water-soluble impurities like glycerol, etc. Hence it is essential to make crude palm oil edible at an affordable cost than others with all the nutrients.

So, check out the many processes done by the best palm oil processing plant in India, including fractionation that removes impurities and increases its shelf life.

What are the Many Processes of India's Best Palm Oil Processing Plant?

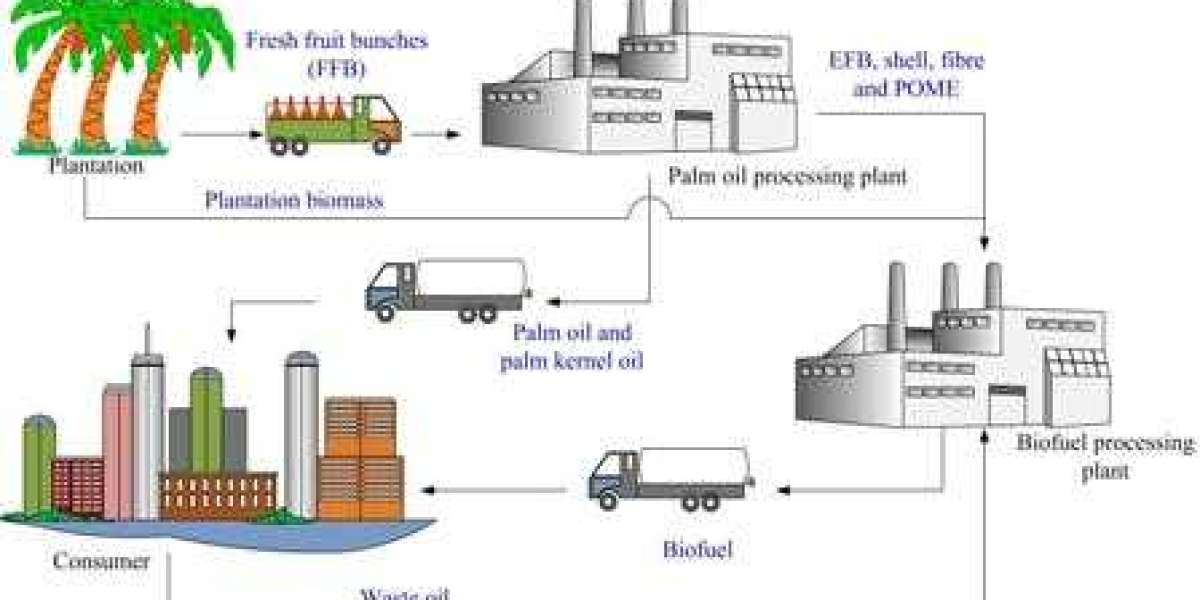

Palm oil manufacturing is one of the largest industries worldwide as it is a significant cooking oil in many countries, including India. There are two types of palm oil extracted from palm fruit flesh, and the other is palm kernel oil extracted from its kernel or seeds. Most countries manufacture palm oil from the fruit by centrifugation and pressing to come out as dark yellow or yellow-red with a sweet taste. Since crude palm oil contains many impurities and nutrients, refining it to remove impurities and keep the flavor, color, and stability, along with increasing its shelf life, is critical. Though many processes are done by the best palm oil processing plant in India, fractionation is the most important. It helps to refine 95% of the crude palm oil apart from the bleaching, deodorization, or deacidification processes.

What is Fractionation Refining of Palm Oil?

After the bleaching and deodorization processes for refining of palm oil, it is the fractionation process. The first step is to cool cold fractionated oil to have maximum regeneration, which is again cooled up to 40 to 45 C using cooling towers using outgoing chilled fractionated oil through filters. It is then chilled in the crystallizers to fractionation temperature to form wax or stearin crystals. Then the crystals get separated from palm olein by feeding through the filter press.

The above facts will help you buy the best palm oil processing plant in India from Mectech, which provides complete operation control using PLC or SCADA automatic electronic panels for optimum performance.